Heuristics are learned through experience - shortcuts that help organize concepts and information into a useful form or solution. Heuristics are simple rules. Use them when information is limited.

Math models work well with risk.

Heuristics work well in uncertain environments.1) Avoid creation of hazardous or toxic materials in the treatment process, If there are hazardous materials in your waste stream and you can transform them to something not hazardous with a reaction, use an excess of non-hazardous reactants to completely consume the hazardous material.

2) Consider purge streams to avoid build up of inert materials. Be careful to avoid purging of hazardous materials.

Size Reduction of Solids

Use a jaw crusher to reduce lumps of hard, abrasive, or sticky materials to slabby materials of 1 to 4 inches

Gyratory crusher to pieces 1 to 10 inches. Gyratory crushers can produce particles that are more rounded.

Cone crusher reduces to 0.2 in to 2 inches.

Rod mill takes particles as large as 20 mm and grinds to 10 to 35 mesh

Ball mill takes particles 1 to 10 mm and reduces to 140 mesh.

Ball mills, tube mills or pebble mills can produce even finer outputs.

Liquid Storage

Liquids that are subject to breathing losses can be stored in tanks with floating or expansion roofs. Although the amount of material in inventory is highly plant-specific, many process plants specify 30 days worth of capacity, for both raw materials and products.

Heat treatment and incineration.

1) The stoichiometric temp of a flame from natural gas combustion is 3500 F. In practical operation with excess air to achieve complete combustion, temp is more like 2000 F. Stack gas is 650 to 950 F so as to avoid condensation.

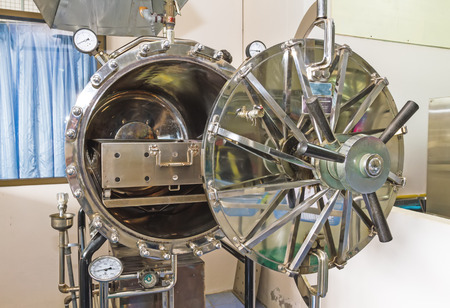

2) An autoclave is a vertical cylindrical stirred tank reactor. Can be operated continuously or batchwise, rates of temperatures, pressures, and rates. Internal agitators (propellers or turbines) or forced circulation with external pumps. Autoclaves can be rocked or tumbled to stir the contents. Steam goes into an external jacket or internal coil.

A useful cost estimation trick: If you know the cost of a waste treatment system, the cost of a smaller or larger system can be estimated using the 0.6 exponent. You have to know the capacity of the two systems, and then the cost varies as the ratio of the capacities to the 0.6 power.

If C1 = known cost of existing system

And

X1 = capacity of existing system

And

X2 = capacity of new system,

Then C2, estimated cost of new system is

C2 = (X2/X1)^0.6

Note this works for capital cost. Operating cost is more likely to scale linearly with capacity.