A landfill is a facility designed for solid waste disposal into the ground. A well-engineered landfill is safe, minimizes adverse effects to public health, and prevents leachate leakage into the soil or groundwater. Landfills may be categorized according to their design: open dumps, basic landfills, sanitary landfills, and bioreactor landfills. In addition, they can be classified based on the type of waste they accommodate, such as municipal, industrial, and hazardous wastes.

Open dumps are the simplest form of landfilling and the oldest form of solid waste disposal. At these sites, waste is usually not inspected or classified by the landfill operators; they take pretty much anything. In addition, no specific criteria are followed for site selection, and few measures are taken to ensure damage to the environment.

Basic landfills are the most common type of landfills in developing countries. Many landfills, even the basic ones, follow a pattern where operators compact the waste within days of dumping, and cover new waste with dirt or mulch. Sometimes, these facilities feature a collection or flaring system to remove the gas produced by waste decomposition.

Sanitary landfills are engineered to provide more control over the various aspects of the landfilling process. In landfill operations a waste-laden truck drives to or on top of the existing waste, and deposits its contents. Other vehicles such as tractors spread the waste out to produce a flatter profile. But driving over the waste, the weight of the vehicles compresses the new waste to reduce its volume. At the end of the operating day, cover material is placed on the new waste.

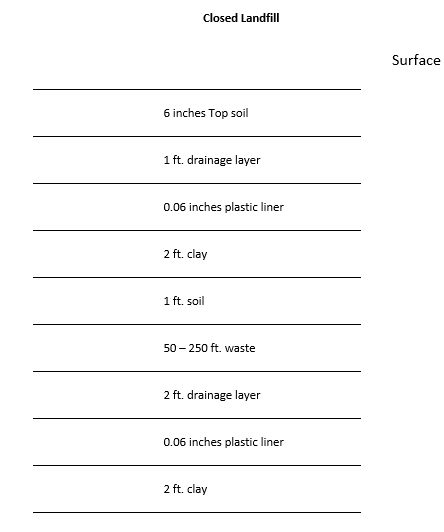

Typical dimensions are:

A volumetric ratio of waste to cover of 4:1 is common, so the cover soil ends up being a good portion of the material in the landfill. The overall height is typically 10 to 15 ft before that area of the landfill is "complete", and new waste is placed elsewhere. The overall waste deposit is usually a dish shape with a slope of 3:1.

In addition, sanitary landfills are designed with leachate control and gas collection systems (gas collection tends to be about 85% efficient). The three types of sanitary landfills are manual, semi-mechanized, and mechanized. Manual sanitary landfills are used in small towns with waste production of less than 15 tons per day, where it is not feasible to employ heavy equipment in the disposal. Instead, the waste compacting and disposal processes are performed by human operators. Mid-sized landfills (16-40 tons per day) are often semi-mechanized: a mixture of human labor and heavy equipment, such as bulldozers is employed in the compaction and filling processes. Landfills that take in more than 40 tons of waste per day are mechanized. Heavy machinery designed for solid waste disposal and treatment, such as solid waste compactors, loaders, and dump trucks are used.

The fourth type is the bioreactor landfill. Like sanitary landfills, bioreactor landfills are carefully designed. However, they are intended to improve the decomposition of the biodegradable fraction of the solid waste. Bioreactor landfills require monitoring of many parameters, such as temperature and pH, because biodegradation is a very sensitive reaction. There are two types of bioreactor landfills: aerobic and anaerobic. In aerobic bioreactors, air is injected into the waste and the decomposition is carried out by aerobic bacteria, while in the anaerobic type, the decomposition occurs in the relative absence of air by anaerobic bacteria. Gas produced in anaerobic landfills is combustible, containing a high percentage of methane. In both types leachate is collected and reinjected into the system to maintain the moisture content.

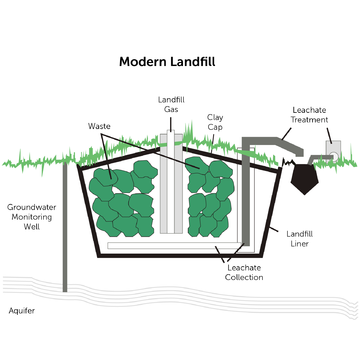

Sanitary landfills are more common than bioreactor landfills. Their essential components are:

Sanitary landfills are more common than bioreactor landfills. Their essential components are:

In addition, well-engineered landfills should have closure plans that explain operations will be terminated when the facility is full and the extent of post-operation monitoring to be conducted.

Landfill location is an important design parameter. The site selection process comprises choosing criteria for the location, listing potential sites, collecting data about each site, screening the available sites to determine the best two or three choices, conducting environmental impact assessment for the best candidates, and final selection of the most appropriate site. A landfill site should be located an appropriate distance from the major bodies of water, e.g. rivers and lakes. Locations of sensitive habitats, highways, public areas (e.g. parks), and areas with groundwater tables within two meters of the surface.

When planning capacity for new landfills, engineers take into account the rate of current waste production in the area and that predicted for the planned lifetime of the landfill. An additional 15 percent in area is added to permit space for operational features such as leachate and gas collection. Landfills are classified as small if their surface area is less than 5 hectares (12 acres), mid-sized if they are between 5 and 20 hectares, and large is they are bigger than 20 hectares (49 acres).

The NAICS code for landfills is 562212. In 1996, the EPA said there were 3436 landfills in the US. The number has declined, but the EPA no longer maintains a list of landfills. A more recent report states that there are over 1,250 landfill facilities in the United States.

Leachate: water that has passed through or emerged from solid waste and which may contain soluble or suspended material.

Landfill Gas: gases produced by decomposition of solid waste. Mostly methane and carbon dioxide with trace amounts of nitrogen, oxygen, hydrogen sulfide, hydrogen, and other organic compounds. Potentially dangerous.

Aerobic Decomposition: breakdown of waster in a landfill that takes place in the presence of oxygen. Produces carbon dioxide.

Anaerobic Decomposition: breakdown of waster in a landfill that takes place in the absence of oxygen. Produces methane and carbon dioxide.

Liner: an engineered layer of recompacted soils and/or synthetic materials that prevents the flow of leachate into groundwater and to facilitate the collection of leachate.

Liners are often called flexible-member liners (FML) and are usually plastic or rubber. Thickness is 0.25 mm (10 mils) to 2.5 mm (100 mils) Liners should be durable, impermeable, non-decaying, chemically compatible with material. Important attributes in a liner are thickness, density, tensile strength, tear resistance, and resistance to low temperatures. Many materials are used: Polyvinyl chloride, High-density polyethylene, Chlorinated polyethylene, Chlorosulfinated polyethylene, Ethylene propylene diene monomer (a type of rubber). Manufacturers and landfill operators can propose new materials. The EPA has a test (Method 9090A) for liner material and waste.

When they are installed, liners are anchored to the earth or a concrete structure in the vicinity. Under the liners are often geotextile meshes that provide support and protection.

Land treatment is a rather old disposal method, but still used in some cases. Also called land application, this is both a waste treatment and disposal process. Waste is mixed with soil and spread out on the land and exposed to the Sun and elements. The waste is not buried. Treatment relies on anaerobic decomposition of organic waste. In this sense, it is related to composting.

Related: transfer stations.