Much of process engineering is like accounting: keeping track of materials and energy. Engineers often use mass and energy balances to analyze systems and to design and plan process equipment needs. The cardinal equation is: In - Out = Accumulation. This balance analysis can be applied to overall mass, to an element (e.g. carbon), to energy, and more. This technique is conceptually simple, but it can be powerful and invaluable in the work of waste process engineering. And it’s a “good practice” for any operating facility.

Although it is somewhat artificial, we recommend waste managers do the mass balance for a typical state of operation. Document it and put in your records. This may be useful if you need to pull out a document to show to a regulator or insurance company.

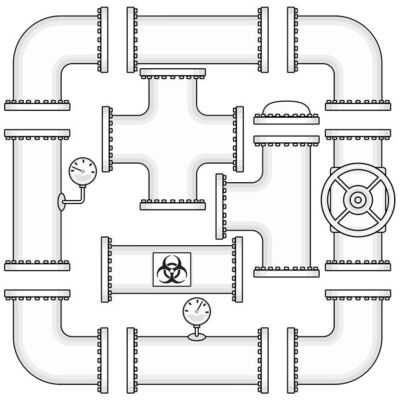

Balances are usually accompanied by a pictorial representation of the process with simplified icons showing tanks, pumps, and other important equipment.

The stream compositions and flow rates are shown on the same sheet with the pictorial representation. . You have latitude in what units to choose: kg/hr, lb/day, etc.

Equipment is often subject to codes and standards. These rules are set by government agencies, insurance companies, and professional organizations. Even when there is no law about your equipment, you should follow industry standards to avoid liability risk in case things go wrong.

Equipment manufacturers sell predesigned "off-the-shelf" equipment with set capacities and sizes. Often these are listed on the manufacturer’s website and prices are fixed. Pumps, filters, and agitators for mixing are in that category. Custom-made, or customized standard equipment, are not fixed price and you need to get a quote from the seller. What do you have to tell the seller? He or she will want as much information as possible, including intended operating conditions and capacity as well as utilities available in the facility (steam, cooling water, electrical outlets, etc.)

Equipment manufacturers sell predesigned "off-the-shelf" equipment with set capacities and sizes. Often these are listed on the manufacturer’s website and prices are fixed. Pumps, filters, and agitators for mixing are in that category. Custom-made, or customized standard equipment, are not fixed price and you need to get a quote from the seller. What do you have to tell the seller? He or she will want as much information as possible, including intended operating conditions and capacity as well as utilities available in the facility (steam, cooling water, electrical outlets, etc.)

Process engineers rarely distinguish between types of tanks unless very specific designs are required. No specialized designs are required for unpressurised liquid storage. Cylindrical tanks are best for stress distribution.

Vertical tanks on legs are often employed for storage of under 100 gallons. For between 100 and 10,000 gallong, horizontal tanks on concrete supports are commonly used. Bigger tanks are vertical on concrete foundations.

For smaller volumes high density poly-ethylene containers are used for temporary storage. These are rarely used as permanent installations in hygienic systems as they are difficult to clean in place.

Tank design is governed by the standard API 620 (it is considered good practice to use the most stringent standard available when designing systems).

Liquid drums usually are horizontal. Drums for gas-liquid separation are vertical

The length-to-diameter ratio is usually about 3 (between 2.5 and 5.0).

Centrifugal pumps are very commonly used in the industry. These pumps are suitable for most applications and are an affordable option for fluid transfer. Commonly the most affordable electric solution for any fluid-moving application. Operating and maintenance costs are low.

Pneumatic pumps are a type of positive displacement pump that commonly uses air to displace fluid. Pneumatic pumps are generally inexpensive. These pumps are very durable and are commonly used in applications where slurries must be transferred, although they function well with other fluids. Operating costs are cheap and maintenance is simple, but due to the requirement of compressed air pneumatic pumps are not always feasible.

Gear pumps are commonly used when high discharge pressures are required (usually due to highly viscous fluids or abnormal pressure drop)

Rotary lobe pumps are very specialised positive displacement pumps which are well suited to pumping high viscosity fluids. Lobe pumps are also frequently used to move sensitive food slurries, and are easy to clean.

Most pump types are sensitive to running dry. See more on piping design.

Common properties:

If the system needs to conform to hygienic standards (the system is resistant to microorganism ingress and growth - standard in the food, beverage & pharmaceutical industries) SS316 is widely considered to be the metal of choice.

Plastics are also sometimes acceptable for hygienic systems and are cheaper and lighter than metals. The use of plastics in food and pharmaceutical environments is governed by the FDAa and EUb regulating bodies. Criteria for the use of plastics are:

| Material | Advantages | Disadvantages |

| Stainless Steel | Several grades available Corrosion resistant Mostly chemically inert Handles most pressure and temperature ranges well Easily cleaned Good lifespan Little to no maintenance required Accepted in hygienic systems | Expensive Requires specialist designers and manufacturers |

| Carbon steel | Potentially cheaper (upfront cost) alternative to stainless steel Performs well in dry systems | Suboptimal corrosion resistance in most wet systems Performs well in dry systems Surface treatment will increase lifetime cost Periodic maintenance required Raw carbon steel is not considered hygienic |

| Plastic | Inexpensive Mostly chemically inert Good lifetime if not exposed to constant direct sunlight Hygienic if designed correctly | Mechanical constraints: Poor handling of pressures, temperatures and loads |

See also: integrated treatment systems.