This type of composting is more widely used in Western Europe than in the rest of the world.

This system avoids the need to mechanically mix the compost material by inserting air input devices that affect air flow through the pile. This is therefore aerobic composting, rather than anaerobic composting. Compared to other composting systems, ASP works quickly. The EPA says compost will be produced in 3 to 6 months.

Sometimes called the “rotting tunnel”, this technology is modular and even though it is a batch process (like all composting systems), it can accommodate swings in rate of waste received by closing off the tunnel into different cells. This composter accommodates animal products in the feed.

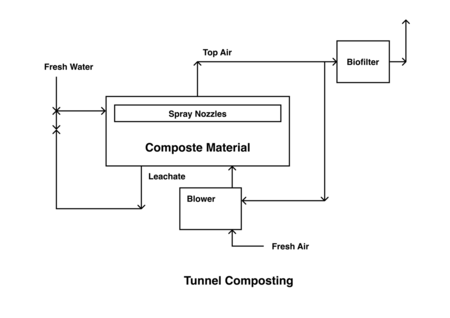

Air that has passed through the compost material is the “top stream”. Part of the top stream goes through a biofilter (for odor removal) and exits to the atmosphere.

Part of the top stream is recycled and mixed with fresh air and goes through the blower back through the aeration at the bottom of the unit.

Opposite to the air flow is the flow of liquid water, which is introduced through a sprayer at the top of the chamber. It percolates through the waste and is collected at the bottom for reuse. This water, which can be called leachate, is pumped back to the top. Fresh water is added to make up for the water that exits as vapor in the exhaust.

The variables affecting composting include oxygen, moisture content and temperature. Operators usually aim for a temperature of 60 °C. The composting process is exothermic (microbial breakdown of material yields heat) and the operators can change the air flow rate to control the temperature.

In-vessel composting has several benefits including fast conversion rates and limited odor. Systems use rotating metallic drums and air blowers to keep oxygen levels up and temperatures down.

In-vessel composting is widely used on municipal solid waste, but most wastes with a significant organic component can be composted. This is aerobic composting. A mixed waste stream can be accommodated with inorganic materials being screened out after the compost forms.

Waste treatment designers incorporate in vessel composting into treatment systems for several reasons:

Windrow composting is done on a large scale. It requires land and regular attending to by personnel. Windrows are rows of waste/compost material - 6 to 8 ft high, 12 to 15 ft wide, and long, usually over 100 ft, although they can be shorter. Windrows are outdoors and this is intended as aerobic composting. By turning the material - mixing it - operators make sure air can get throughout the pile and moisture does not accumulate in any one part of the pile. Turning also prevents the material from overheating. Some temperature elevation is good - maybe 30 degrees F above ambient. Ideal composting conditions include water, air, and heat.

In Windrow composting, the compost is usually "finished" in two months or so. This type of composting is used widely in agricultural areas.