Types of incinerators

Pyrolysis is heat treatment with insufficient air to support full combustion. Some of the waste burns and adds to the heat production (along with fuel, typically natural gas). The rest of the combustible material in the waste may not burn or only partially oxidize. However, the high temperatures can cause chemical reactions and destruction of hazardous compounds even without oxidation. This is called pyrolysis.

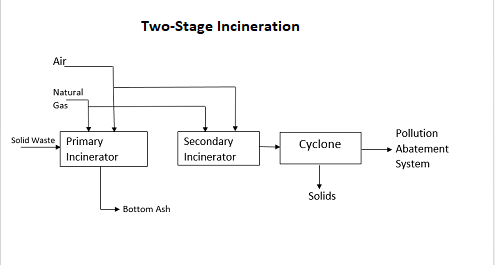

Starved-air incineration systems for waste treatment are always two-stage systems. The waste is processed in batches (as opposed to continuously.) In the first stage, the waste stays in the chamber for an hour or more. Temperature of operation is on the order of 1500°F. Gases given off exit the top of the chamber and enter a fired afterburner where it is burned again. The afterburner exhaust is quenched with water and enters a scrubbing system to remove particulates and acid gases before going to the atmosphere.

At the end of the heating time, residual solids are removed and allowed to cool. Then it may be tested or checked for hazardous material. If needed, it goes for further treatment (either heat treatment or chemical treatment). Otherwise, it is packaged for disposal in a landfill. (This packaging may include encapsulation.)

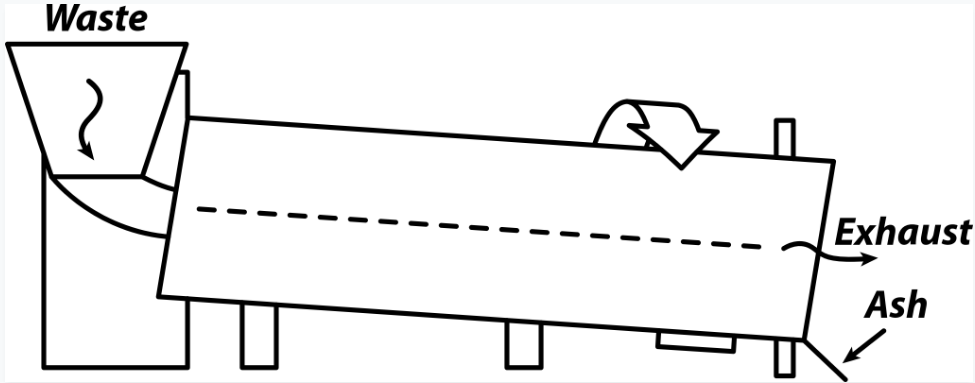

Rotary kiln incinerators are large and have capacities to treat high waste flowrates - on the order of tons per hour. If you have seen a cement kiln, you have seen something like the kind of rotary units used to burn waste. The shape is cylindrical and on a slight slope. They rotate during operation and there is an internal baffle which moves solids down the cylinder. Waste enters the upper end of the kiln. The residence time is how long it takes until the solid residue comes out the other end.

Heating is provided typically by natural gas at the lower end of the kiln. The gases flow from the lower end to the upper end, opposite the direction of travel of the solids. After they exit the main kiln, the gases may enter a fired afterburner, and then proceed to a quench and scrubbing system. The gas in the kiln is on the order of 2000 °F.

Rotary kilns are usually operated continuously because they take so long to heat up. They are thus most appropriate for treatment of large quantities of waste. The most expensive of commonly used incinerators, rotary kilns are used for medical waste treatment in major collection centers.

Another problem with incineration is mercury emissions. Although operators take precautions against introducing mercury into their units, it was estimated in 2006 that 13 percent of man-made mercury emissions was due to incineration of waste. Most of the rest was due to burning of coal.

Ship-mounted incinerators will burn your waste for a fee. The advantages of burning waste at sea is that it is away from population centers and, if far enough from land, is free from national laws and regulations. That means the incinerators can be less efficient and pollute more. Ash from the incinerators is often dropped into the ocean.

There may be international treaties about these operations - such regulations are beyond the scope of this website. The waste manager may have ethical problems with these solutions as they seem an “easy out” and way to skirt the rules and to be irresponsible.

Mobile incinerators tend to be small; getting a mobile incinerator to pass EPA regulations can be a challenge. They are usually less efficient and often more prone to creating furans and dioxins in the exhaust.

Small-scale incinerators were once common in the United States and are still used in much of the world. An apartment building may have had an incinerator for disposing of residents’ waste and to provide heat. Most hospitals had incinerators. They were generally less efficient and more prone to releasing pollution than large, well-engineered incineration systems. While small incinerators are almost always superior to dumping medical waste with no treatment, they should be considered only if there is no better solution available.

In the 1990s engineers at Du Montfort University in the UK developed a small incinerator for treatment of medical waste. They were intended for use in developing countries and they have found success over the years, even as the design has evolved.

Learn more here: https://mw-incinerator.info/en/101_welcome.html

Both use high temperatures to effect chemical reactions that make change the nature of the waste. Pyrolysis is heat when the heating takes place with substoichiometric amounts of oxygen. There is probably some oxidation; this oxidation often provides the heat. (This is how charcoal is made.) But there is not enough oxygen to burn the constituents to completion. Incineration is when there is enough - and usually an excess - of air. Almost all carbon is converted to carbon dioxide. Sulfur is converted to sulfur oxides and some nitrogen oxides may form, although most nitrogen remains in the elemental form.. The output from incineration is gaseous products and ash. The output from pyrolysis can include solids with some heating value remaining (e.g. charcoal). In properly engineered systems both operate at temperatures and residence times adequate to kill bacteria and fungi and to disable viruses.

| Pyrolysis | Incineration |

| 500 °F - 1300 °F | 1500 °F - 2600 °F |

| Stoichiometric ratio of Oxygen = 0 | Stoichiometric ratio of Oxygen > 0 |

| Solid phase product: ash, coke, charcoal | Solid phase product: ash, slag |

| Liquid phase product: pyrolysis oil, water | Liquid phase product: none |

| Gas phase product: CO2, CO, C2H4, C2H6, H20, H202, N2 | Gas phase product: CO2, H2O, N2, O2 |

Between 1998 and 2008 the number of medical waste incinerators in the US declined by 99 percent. Incineration has fallen out of fashion not just for treating medical waste but for handling all sorts of waste. It’s a shame because in many cases incineration is the most effective technology for safely treating waste and one that can truly convert something that is hazardous to something that is not hazardous.

Once almost every hospital had an incinerator. And the incinerator may not have been dedicated just to medical waste, but to waste disposal in general. Indeed, all sorts of buildings - office buildings, residential apartment complexes, etc. - had incinerators. By today’s standards they were inefficient and possibly hazardous. But cities had hundreds of incineration units running every day. That was partly why air pollution was worse years ago. These were single-chamber incinerators without adequate controls for air flow or residence time or temperature and combustion was often incomplete. They did not necessarily have pollution control measures operating and emitted smoke.

But society turned against incinerators. Mostly for good reason, but we argue the anti-incineration trend went too far. While in the past buildings burned their trash, now they pay someone to haul it away. Building heating is more often electric or natural gas. Fuel oil is less often used. And the heating units that do use fuel oil are cleaner than they once were. You don’t see smoke coming out of those units today. While in the past, building managers might have tossed building trash into the furnace, thereby killing two birds with one stone (cutting both waste disposal costs and heating costs), nobody does that anymore.

An alternative is to have fewer but larger incineration facilities and to make those incineration facilities environmentally responsible. The remaining hospital waste that is incinerated in the US goes into such a system. Incinerators are large and have pollution abatement systems.

The organization Health Care Without Harm, an international non-governmental organization that campaigns for cleaner and safer healthcare practices, has come out against incineration. They cite the possibility of toxic materials in incinerator emissions, and the fact that effluent can travel hundreds of miles from the incinerator.

Design of Incineration Systems

Related: Molten Salt Oxidation

Locations of Some Treatment Facilities