Reducing production of waste is - other things being equal - almost always a good idea. It saves money on treatment and disposal costs and it reduces liability risk.

Clinics and centers can reduce their waste costs by choosing wisely in purchasing and by proper inventory management. It takes some thought, but (1) picking supplies that produce a less hazardous waste product and (2) using as much as possible (preferably all) of the material in a container benefits your overall waste management profile. An inventory control system may help reduce waste production, as well as adopting a just-in-time delivery system for supplies.

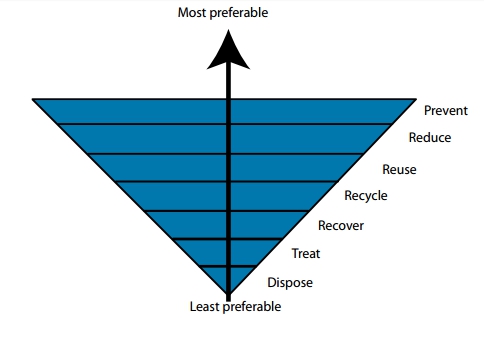

The 1984 amendment to RCRA made waste minimization "the nation's preferred hazardous waste management practice."

The 1990 Pollution Prevention Act says "the national policy of the United States that pollution should be prevented or reduced at the source whenever feasible". The objective of pollution prevention is to reduce the overall level of risk in all areas and not to shift risk from one type to another. "Risk shifting" is a trap that planners and engineers sometimes fall into - reducing pollution in one area while making the environmental sitation worse elsewhere.

There is little the government can do to force producers to minimize waste, but the waste management community agrees reducing production of waste is an admirable goal and often pays for itself or yields a positive return on investment. You can reduce waste in many ways. Techniques such as product substitution and process substitution can reduce the quantity of end waste and often lower the toxicity of the waste. Of course, blindly cutting waste production is not always a good idea. There are diminishing returns past a point, and competing demands (e.g. the need for patient care) means it isn't always preferable to cut waste.

Waste minimization shouldn't be a program so much as a guiding theme in running your facility. Don't think of it like a New Year's resolution. Think of it as a part of your operational philosophy.

The US hospital industry has a website called Sustainability Roadmap for Hospitals. It claims "many hospitals routinely throw from 50-70% of their waste into" a regulated waste stream when the actual percentage of waste that needs to be considered regulated waste is closer to 10 percent. We tend to doubt very many hospitals are that bad at segregation, but whatever the number is, there are surely opportunities for savings.

One great way to start is with how you bring materials into your facility. Some organizations have adopted an environmentally preferable purchasing (EPP) philosophy.

This means choosing items likely to generate low quantities of final waste when they leave the building, and that are less likely to include, release, or cause generation of hazardous materials.

Decades ago hospitals and medical centers bought mercury thermometers. These posed risks and caused costs to incur when they broke and required cleanup of mercury waste and subsequent disposal. You rarely see mercury thermometers any more.

Other EPP and inventory management tactics include:

Polyethylene, polypropylene, and polyethylene terephthalate (PET) are easily recycled plastics. Polyvinyl chloride (PVC) is the most problematic of the common plastics. It is sometimes difficult to choose the best EPP products, and few organizations make it their only decision criteria (cost still counts). But over time you may be able to reduce the negative impact your organization has on the environment and build a more sustainable operation. Actions like buying recycled paper where it can be used contribute to EPP. Adopting life-cycle thinking in evaluation of major purchases also could be a goal. Also, over time you can push your suppliers to be more economical in use of packaging material.

Corporate programs have been developed and can help. Johnson and Johnson introduced their Earthworks program with an eye to making their products more eco-friendly. While many of the products they claim as success stories under this program are consumer goods (e.g. shampoo), also included are clinical products sold to hospitals and medical centers.

Often the facility's waste management plan has a section describing waste minimization goals. Possible good ones:

Be as quantitative as possible. For example: Not “increase use of recycled paper” to “increase use of recycled paper to 40 percent.”